Large-scale logistics sorting hubs equipment expert-construction site

Release Time : 2024-12-25

Project Overview

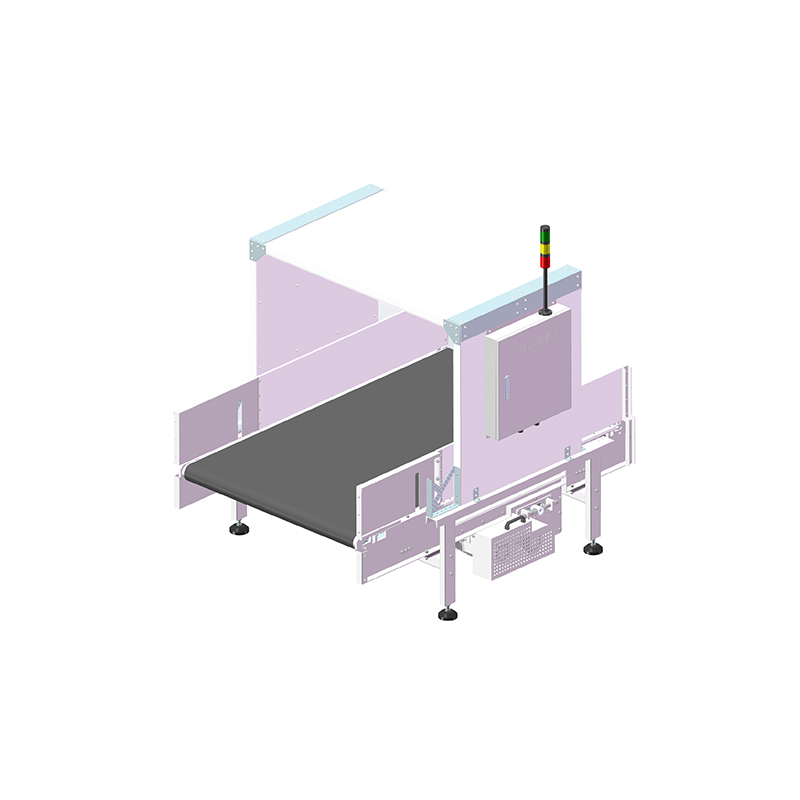

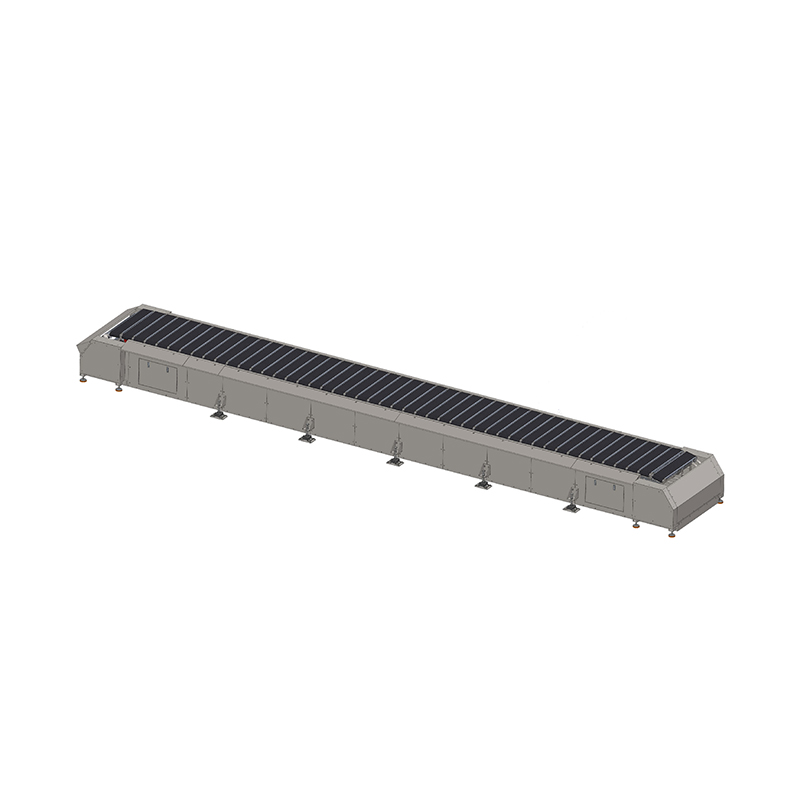

The logistics sorting hubs project located in a certain place covers a total area of 130 acres, with a total construction area of more than 14,000 square meters and a total investment of up to 170 million yuan. After the project is fully completed, the average daily parcel processing volume will reach 5 million orders, becoming an important hub for regional smart logistics. The center is equipped with a variety of advanced intelligent conveying and sorting equipment such as belt conveyors, box roller conveyors, narrow belt sorters, swing wheel sorters, parcel single piece separators, 3D scanning systems, RFID channel machines, whole belt confluence machines, fire telescopic machines, loading and unloading belt telescopic machines, etc.

Phased implementation status

At present, the project has completed the construction of the main structure of the building and entered the critical stage of equipment installation and system commissioning. The site is divided into sections and scientifically planned to ensure the simultaneous improvement of project safety, quality and efficiency.

Equipment foundation installation completed

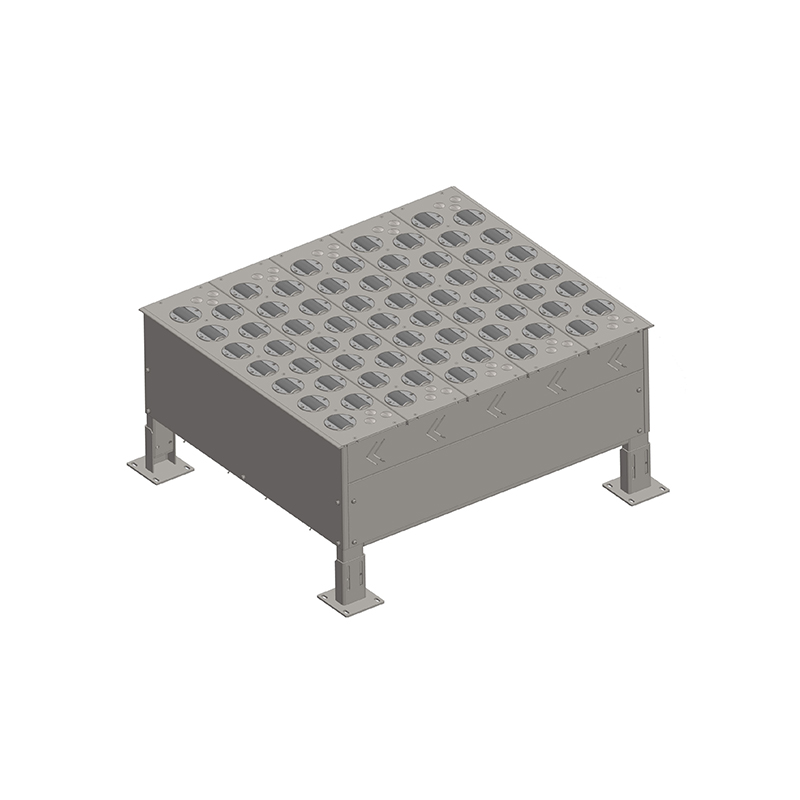

The basic framework installation of all conveying and sorting equipment has been completed, including the bracket fixing of belt conveyors and box roller conveyors and the preliminary layout of whole belt confluence machines and loading and unloading belt telescopic machines. At the same time, the location debugging of various core equipment and the preliminary docking with the power system have been basically completed, laying the foundation for subsequent joint debugging and testing.

Optimization of intelligent system layout

In order to improve operating efficiency, the construction team cooperated with the technical team to optimize the equipment layout to make the sorting process smoother. The location of the 3D scanning system and the RFID channel machine has been tested and adjusted many times to ensure the accuracy and real-time nature of package information collection; the layout of the pendulum sorter and the narrowband sorter fully considers the load capacity during peak hours and reasonably diverts different types of packages.

Parallel debugging and safety assurance

At present, some equipment has entered the single-machine debugging stage, and technicians have repeatedly tested the operating speed, accuracy and safety. The construction site strictly implements the safety management system, holds engineering coordination meetings every day, and focuses on checking the risks of high-altitude operations and power construction links.

Next plan

The project team will complete the linkage debugging of all equipment in the next two months, including the docking of the intelligent sorting system and the information management platform, to ensure that the system can operate stably after it goes online. At the same time, the operation training of on-site staff will be gradually promoted to provide strong support for the subsequent operation of the project.

Summary and Outlook

The logistics transfer center project has now entered the mid-to-late stage of scientific and orderly advancement, and equipment installation and commissioning are progressing smoothly. After completion, the project will significantly improve regional logistics efficiency, help companies reduce costs and improve service capabilities, and become a benchmark project for the intelligent development of the industry.