Intelligent diagonal belt conveyor: the key driver of efficient logistics system

Release Time : 2024-12-11

In the field of modern logistics, with the booming development of e-commerce and the increasingly close global supply chain, efficient and accurate item handling and distribution capabilities have become one of the core elements of corporate competitiveness. In this context, the intelligent diagonal belt conveyor, as a conveying equipment designed for complex logistics systems, is gradually showing its irreplaceable value.

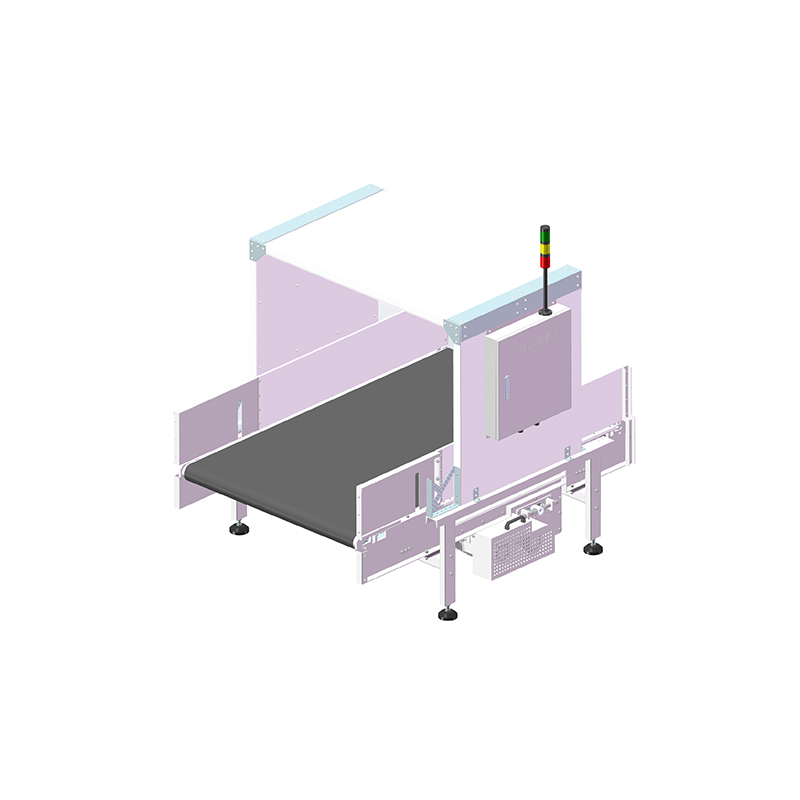

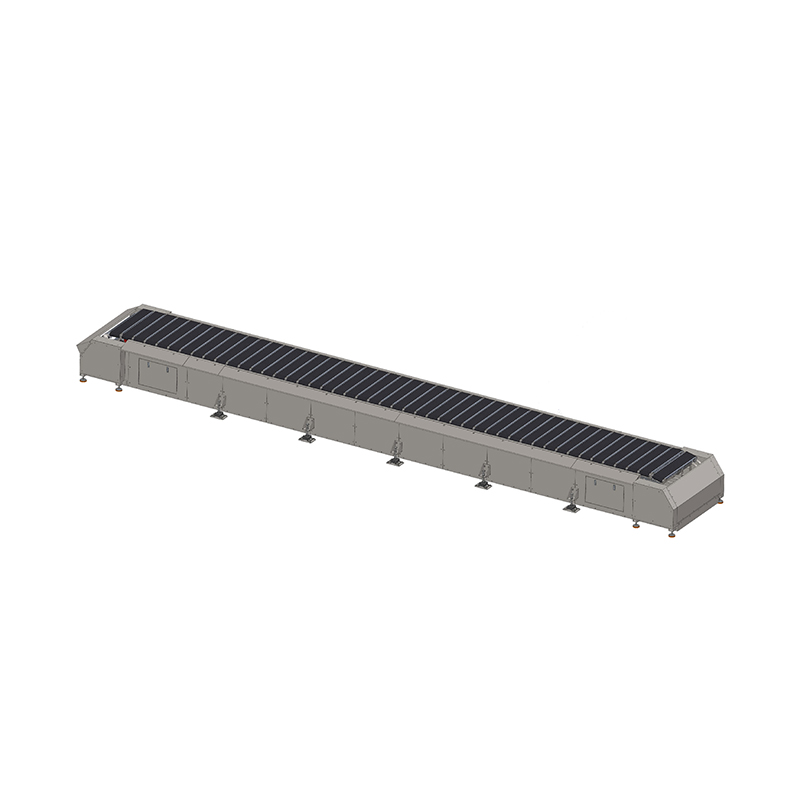

Overview of intelligent diagonal belt conveyor

As the name suggests, the oblique belt conveyor is an advanced device that uses an inclined belt as a transmission medium to integrate and guide the flow of items from multiple input points. Its design cleverly lifts items from low to high, or smoothly transitions between workstations at different heights, effectively solving the limitations of traditional conveying systems in dealing with height differences. More importantly, the intelligent diagonal belt conveyor incorporates advanced automation and intelligent technologies, such as sensor technology, the Internet of Things (IoT), and big data analysis, making the control of item flow more accurate and efficient.

Core technical features

Intelligent control: By integrating advanced control systems, the intelligent diagonal belt conveyor can adjust the running speed, tilt angle and even the item sorting path according to preset logic or real-time data, ensuring high flexibility and responsiveness of the logistics process.

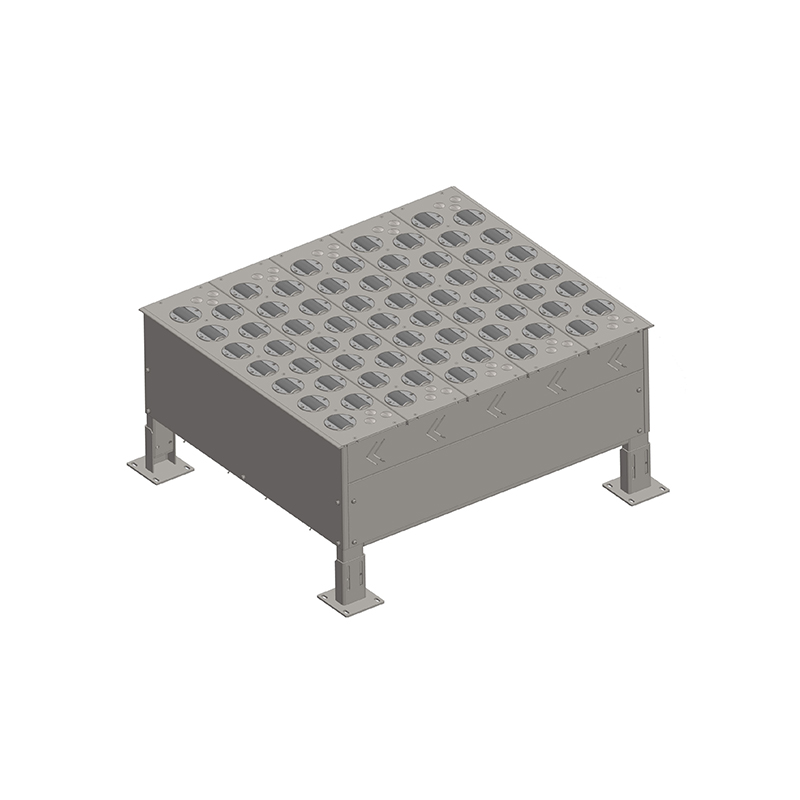

Efficient integration: It is particularly suitable for processing item flows from multiple input sources (such as automated sorting lines, manual workstations, etc.). Through intelligent scheduling algorithms, it can achieve rapid integration and orderly output of items, significantly improving logistics efficiency.

Precise tracking: Using technologies such as RFID and barcode scanning, each item is tracked and recorded in real time to ensure the accuracy and traceability of logistics information, providing solid data support for subsequent inventory management, customer service, etc.

Energy saving and environmental protection: The use of energy-saving motors and optimized design can reduce energy consumption while reducing unnecessary wear and tear through intelligent adjustment, extending the service life of equipment, in line with the development trend of green logistics.

Application scenarios

Intelligent diagonal belt conveyors have shown extensive application potential in multiple industries, especially in the following key scenarios:

Sorting center warehouses: In large e-commerce warehouses, intelligent diagonal belt conveyors can efficiently connect various sorting areas to achieve rapid sorting and transfer of packages, reduce manual intervention, and improve sorting accuracy.

Manufacturing plants: On production lines, they are used to transport raw materials, semi-finished products and finished products to ensure smooth production processes and improve overall production efficiency.

Postal services: Facing the processing needs of massive mail and parcels, intelligent diagonal belt conveyors can automatically complete a series of operations such as sorting, packaging, and loading, shorten mail processing time, and improve customer satisfaction.

Intelligent diagonal belt conveyors are gradually becoming an indispensable part of modern logistics systems with their high efficiency, flexibility, and intelligence. It not only optimizes the logistics operation process and improves processing efficiency, but also brings unprecedented changes to the logistics industry through the application of intelligent technology. With the continuous advancement of technology and the continuous expansion of application scenarios, intelligent diagonal belt conveyors will play a more important role in the future development of logistics, driving the entire industry towards a more efficient, green and intelligent direction.

Overview of intelligent diagonal belt conveyor

As the name suggests, the oblique belt conveyor is an advanced device that uses an inclined belt as a transmission medium to integrate and guide the flow of items from multiple input points. Its design cleverly lifts items from low to high, or smoothly transitions between workstations at different heights, effectively solving the limitations of traditional conveying systems in dealing with height differences. More importantly, the intelligent diagonal belt conveyor incorporates advanced automation and intelligent technologies, such as sensor technology, the Internet of Things (IoT), and big data analysis, making the control of item flow more accurate and efficient.

Core technical features

Intelligent control: By integrating advanced control systems, the intelligent diagonal belt conveyor can adjust the running speed, tilt angle and even the item sorting path according to preset logic or real-time data, ensuring high flexibility and responsiveness of the logistics process.

Efficient integration: It is particularly suitable for processing item flows from multiple input sources (such as automated sorting lines, manual workstations, etc.). Through intelligent scheduling algorithms, it can achieve rapid integration and orderly output of items, significantly improving logistics efficiency.

Precise tracking: Using technologies such as RFID and barcode scanning, each item is tracked and recorded in real time to ensure the accuracy and traceability of logistics information, providing solid data support for subsequent inventory management, customer service, etc.

Energy saving and environmental protection: The use of energy-saving motors and optimized design can reduce energy consumption while reducing unnecessary wear and tear through intelligent adjustment, extending the service life of equipment, in line with the development trend of green logistics.

Application scenarios

Intelligent diagonal belt conveyors have shown extensive application potential in multiple industries, especially in the following key scenarios:

Sorting center warehouses: In large e-commerce warehouses, intelligent diagonal belt conveyors can efficiently connect various sorting areas to achieve rapid sorting and transfer of packages, reduce manual intervention, and improve sorting accuracy.

Manufacturing plants: On production lines, they are used to transport raw materials, semi-finished products and finished products to ensure smooth production processes and improve overall production efficiency.

Postal services: Facing the processing needs of massive mail and parcels, intelligent diagonal belt conveyors can automatically complete a series of operations such as sorting, packaging, and loading, shorten mail processing time, and improve customer satisfaction.

Intelligent diagonal belt conveyors are gradually becoming an indispensable part of modern logistics systems with their high efficiency, flexibility, and intelligence. It not only optimizes the logistics operation process and improves processing efficiency, but also brings unprecedented changes to the logistics industry through the application of intelligent technology. With the continuous advancement of technology and the continuous expansion of application scenarios, intelligent diagonal belt conveyors will play a more important role in the future development of logistics, driving the entire industry towards a more efficient, green and intelligent direction.